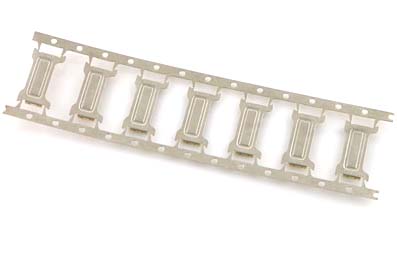

Electronic Stampings Parts

- PRODUCT DETAIL

The surface and intrinsic properties of electronic stamping materials have a great influence on the quality of stamped products. The thickness of stamping material is required to be precise and uniform; the surface is smooth, no spots, no flaws, no scratches, no surface cracks, etc.; Uniform yield strength, no obvious directionality; high uniform elongation; low yield ratio; low work hardening.

Classification of electronic stampings

Electronic stamping parts are mainly classified according to process and can be divided into two major categories: separation process and forming process.

The separation process is also referred to as blanking. Its purpose is to separate the electronic stampings from the sheet material along a certain contour and to ensure the quality requirements of the separation section.

The purpose of the forming process is to make the sheet plastically deform without breaking the blank to produce a workpiece of a desired shape and size. In actual production, a variety of processes are often applied to one workpiece.

Common processes: Punching, bending, shearing, deep drawing, bulging, spinning, and rectification are several major stamping processes.

Classification of electronic stampings

Electronic stamping parts are mainly classified according to process and can be divided into two major categories: separation process and forming process.

The separation process is also referred to as blanking. Its purpose is to separate the electronic stampings from the sheet material along a certain contour and to ensure the quality requirements of the separation section.

The purpose of the forming process is to make the sheet plastically deform without breaking the blank to produce a workpiece of a desired shape and size. In actual production, a variety of processes are often applied to one workpiece.

Common processes: Punching, bending, shearing, deep drawing, bulging, spinning, and rectification are several major stamping processes.

Mobile phone TF card metal fittings

|

|

SATA connector housing stampings Parts

|

|

VCM motor shell stamping

Motor housing Motor housingThe motor housing generally refers to the external housing of all electrical equipment. The motor housing is a motor protection device made of silicon steel sheet and other materials by stamping and drawing process. In addition, surface treatment such as rust prevention and spray molding can protect the internal equipment of the motor. Main functions: dust, noise canceling, and waterproof. According to the material to be divided: the shell can be divided into metal shell, plastic shell and so on. In accordance with the use of points: generator shell, starter shell, other digital products motor shell |

|

Riveting parts

The riveted component refers to a component that combines two different materials or electrical contact materials with different properties by means of riveting. The riveted component refers to a component that combines two different materials or electrical contact materials with different properties by means of riveting. |

PREV:Metal Stretching Parts

NEXT:NONE

NEXT:NONE